Apply Here for Financing

AGCO Finance LLC strives to provide you with the solutions needed to secure financing options for your equipment needs. Applying through our simple online application is a key step in determining tailored financing best suited for you. Please note that applications are subject to further credit review and approval and other terms and conditions by AGCO Finance LLC.

GFX-1260™ Display

The GFX-1260™ display is the newest flagship member of Trimble Agriculture’s GFX lineup, offering a 12-inch (30.5 cm) Android™-based display for managing your operations using the Precision-IQ™ field application interface. GFX displays build on Trimble’s history of innovative, user-friendly technology. With enhanced processing power, greater memory, and larger storage capacity, the GFX-1260 shines on any farming operation.

GFX-1060 display

The GFX-1060 display is Trimble’s latest 10-inch (25.6 cm) Android™-based display for controlling and executing operations using the Precision-IQ™ platform.

GFX-750™ Display

The Trimble® GFX-750™ display continues a strong tradition of sleek, easy-to-use displays from Trimble Agriculture. With a roof-mounted guidance controller, your cab will be clean and clutter-free with this automated guidance system. Add in Bluetooth and Wi-Fi connectivity to go along with ISOBUS compatibility and you can tackle farming applications from every season across all of your equipment brands.

GFX-350™ Display

The Trimble® GFX-350™ is the latest Android™ -based, easy-to-use display from Trimble Agriculture. This cost-effective solution offers great functionality and a simplified installation process, providing access to autosteering and application control for every farm. Add in Bluetooth® and Wi-Fi connectivity to go along with ISOBUS compatibility and any grower can tackle farming applications from every season across all equipment brands.

TMX-2050™ Display System

In the middle of a busy season, the last thing you need is a complicated interface. The easy-to-use TMX-2050™ display system features a large high-definition touch screen with sharp visuals and a choice of FmX® Plus or Precision-IQ™ display applications to suit your specific farm practices.

NAV-900 Guidance Controller

The NAV-900 guidance controller is our most advanced GNSS receiver to date, built for maximum uptime and a wide range of accuracy options from basic to high precision. It is designed to mount on the roof of most agricultural vehicles to provide positioning and guidance, including autosteer.

NAV-500™ Guidance Controller

Paired with any GFX series display, the NAV-500™ guidance controller is an affordable precision solution capable of receiving corrections from multiple GNSS satellite constellations. Get sub-meter repeatable accuracy and full-farm coverage at a great price to use during tillage, broad-acre seeding, spraying and harvest.

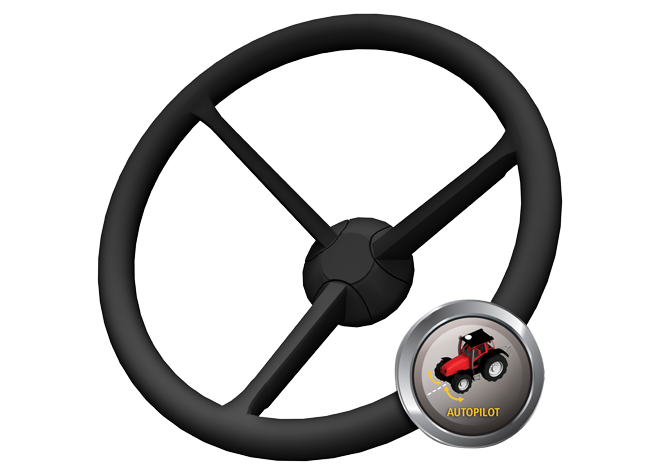

Autopilot™ Automated Steering System

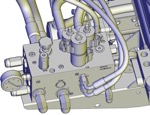

Automated, hands-free, steering system installs directly into the hydraulic system, delivers highest-accuracy steering in any field type. The Trimble® Autopilot™ automated steering system automatically steers your vehicle on line with maximum precision. When your vehicle gets offline, Autopilot signals it to adjust its position to follow the correct path, no matter the field pattern or terrain type — so you can focus on the job ahead of you.

Autopilot™ Motor Drive System

Electric, hands-free, automated steering system with easy installation onto steering column, delivers highly-accurate, Autopilot-level steering. Trimble® Autopilot™ Motor Drive, controls tractors and harvesting machines without hydraulic components up to RTK accuracy. No matter your vehicle type or brand, the Trimble Autopilot Motor Drive system can be quickly installed from one vehicle to another and steers your vehicle on line for maximum precision.

EZ-Pilot® Pro Guidance System

The EZ-Pilot® Pro guidance system offers high accuracy guidance across MFWD tractors, 4WDs, and combines. The added benefit of the EZ-Pilot Pro system is that vehicles are now able to be engaged in reverse to allow them to be lined for the next swath (max 15 seconds). Adding this feature allows users to benefit from a high accuracy solution from the second the implement engages with the soil.

EZ-Pilot® Assisted Steering System

Assisted steering with integrated electric motor drive for high accuracy at an affordable price. The Trimble® EZ-Pilot® assisted steering system provides high-accuracy steering at an affordable price. When you are driving your vehicle, the EZ-Pilot system turns the wheel for you with a compact electric motor drive using guidance from Trimble displays to help keep you on line and improve your efficiency. The versatile steering system is ideal for both low-accuracy broadacre farming applications as well as high-accuracy row crop applications.

EZ-Steer® Assisted Steering System

Assisted steering system providing portable, hands-free farming for more than 1200 vehicle makes and models. The Trimble® EZ-Steer® assisted steering system provides simple, portable, hands-free farming for more than 1200 vehicle models – old and new. The EZ-Steer system turns the steering wheel for you by combining a friction wheel and a motor with guidance from any compatible Trimble display. It keeps your vehicle online for efficient, low-stress steering capabilities for your farming applications.

TrueTracker Implement Steering System

Active implement guidance system that keeps your tractor and implement on the same guidance line. Keep your implement and tractor on the same guidance line with the Trimble® TrueTracker™ implement steering system, an active implement guidance system that allows your implement to guide itself independently from your tractor. TrueTracker uses your tractor’s Autopilot system to monitor your implement and signal it to follow the correct path during periods of drift. TrueTracker keeps you confident that your implement is on line all the time.

TrueGuide Implement Guidance System

Passive implement guidance system that monitors and corrects the position of your implement by moving the tractor. Control your implement with the Trimble® TrueGuide® implement guidance system, a passive guidance system that monitors and corrects the position of your implement with compensation from your tractor. With TrueGuide, your implement’s position Is dependent on your tractor. When your implement drifts, TrueGuide signals your tractor’s Autopilot system to pull the implement on line — so you can operate with ease no matter the guidance path

RG-100 Row Guidance

Combine guidance system that uses sensors to center the combine on rows. With the Trimble® RG-100 row guidance system, you can automatically adjust the combine in response to changes in the rows by using existing sensors built into the combine head. The RG-100 system uses the Trimble Autopilot automated steering system to center the combine on the rows — even when they are not straight.

VerticalPoint RTK™ Grade Control

Whether you’re a grower or a contractor, Trimble® VerticalPoint RTK™ grade control achieves maximum vertical accuracy for all leveling and land forming operations. Increase your productivity with a solution that sets a new standard for uptime with continuous in-field operations.

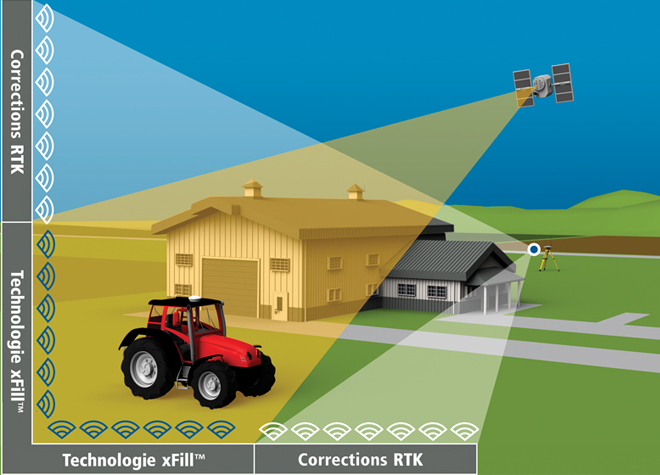

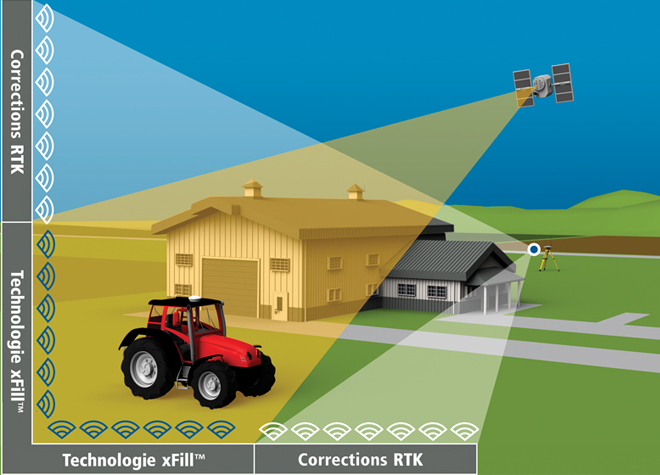

CenterPoint® RTK

Receive RTK corrections within range of an established RTK base station network.

CenterPoint® VRS

Instant access to RTK-level corrections within a fixed network of reference stations. Ideal for drainage, drip irrigation, and land leveling.

Trimble xFill

Powered by Trimble RTX technology, Trimble xFill provides seamless, centimeter-level back-up corrections via satellite if RTK or VRS signal source is interrupted.

CenterPoint® RTX

High accuracy <2.5 cm (1″) correction service, delivered via satellite. Ideal for planting/seeding, spraying, and strip tilling.

RangePoint® RTX

Affordable, mid-accuracy correction service providing < 15 cm (6″) pass-to-pass positioning via satellite. Ideal for broad acre applications.

OmniSTAR

Offers a range of satellite or cellular delivered corrections services from < 10 cm to < 1 meter. Ideal for spraying, spreading, soil cultivation, and more.

ViewPoint® RTX

Trimble ViewPoint RTX, an affordable, entry-level alternative to free-to-air (SBAS) satellite systems that provides 30 cm pass-to-pass accuracy; giving farmers a more stable signal with the same ease of use. This advanced technology in agriculture helps you achieve the quality standards you need in less time when broad-acre farming.

WAAS/EGNOS/MSAS

Standard satellite service on all Trimble displays.

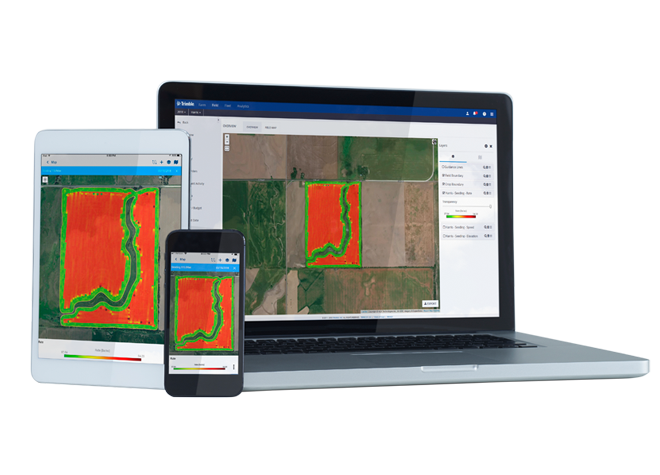

Farmer Starter

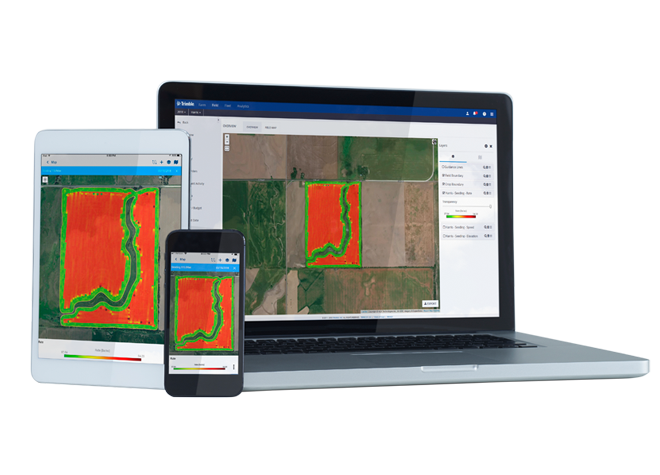

Trimble’s Farmer Starter is a free, easy-to-use online and mobile platform for farmers who want to organize and access their farm data from any device connected to the internet. This innovative farm management software tool provides the perfect starting point and can be seamlessly upgraded to Farmer Pro for additional functionality.

Farmer Core

Connect, simplify, and streamline your entire farm operation with Farmer Core. Trimble’s Farmer Core software complements your existing Trimble system to manage precision farming data and simplify display setup to capture the most value from every acre. Farmer Core is powered by AutoSync™, a new and innovative feature that runs in the background to automatically sync all guidance lines, field names, boundaries, materials, implements, vehicles, and operator information across all connected devices.

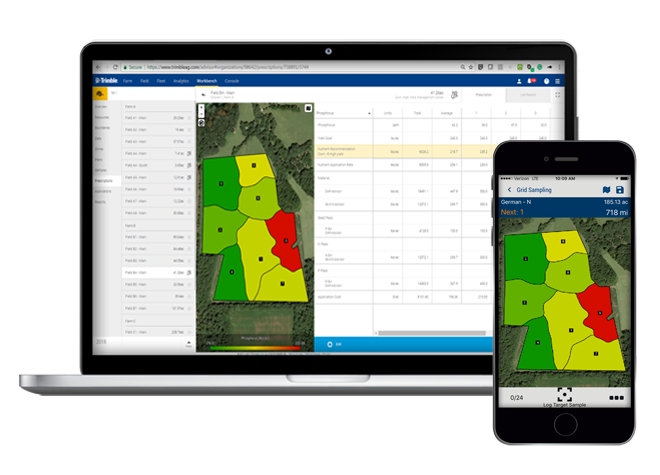

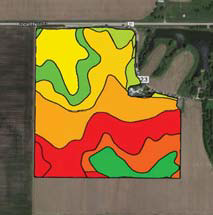

Farmer Pro

Farmer Pro is Trimble’s most powerful online and mobile farm management software. Farmer Pro customers get additional features that enable innovative, profitable farm management, including Crop Health Imagery, Work Orders, grid or zone soil sampling workflows, managing grain contracts, and more.

Ag Premium Weather

Ag Premium Weather is the ultimate agricultural weather application that offers intelligent field-level precision. It provides up-to-date tracking of precipitation, temperature, and growing degree days without the worry of physical rain gauges or expensive in-field hardware. With Ag Premium Weather you get current and historical precipitation data, which will enable you to improve operational planning, anticipate yield potential, and adjust yield goals.

Ag Time Tracker

Ag Time Tracker enables you and your team to stay organized and maximize productivity effortlessly. You’ll get stats on the working time and performance of your team that will help you make profitable, data-driven decisions. With Ag Time Tracker you have the ability to see the GPS clock in/out locations of employees, a feature that supports both safety and accountability.

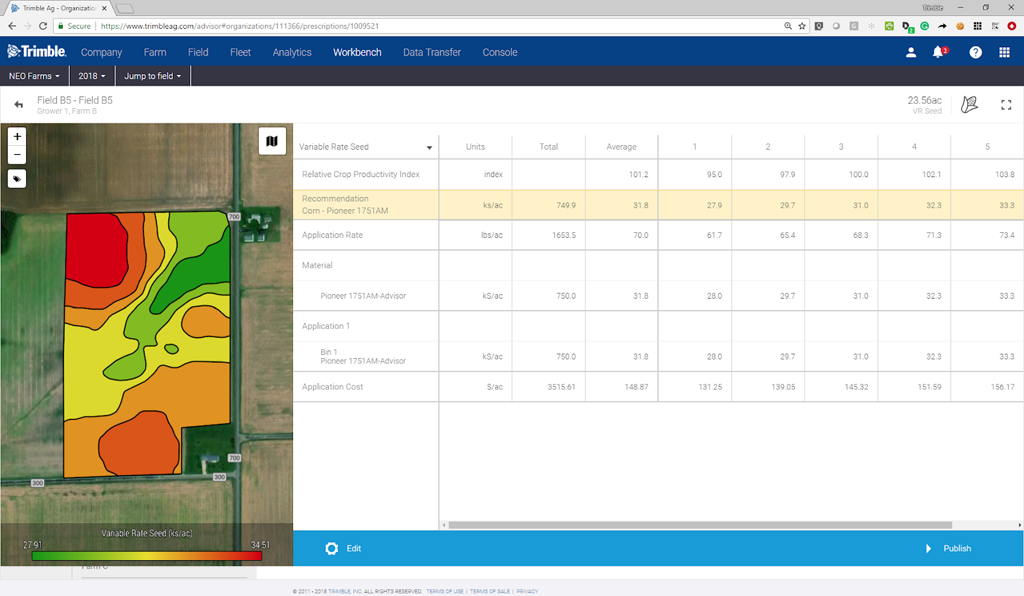

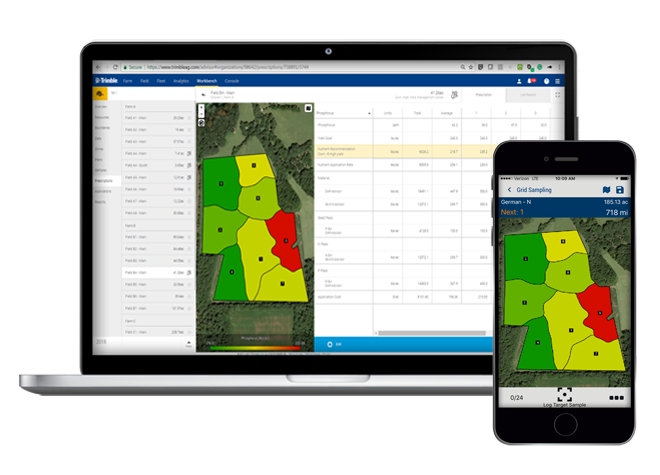

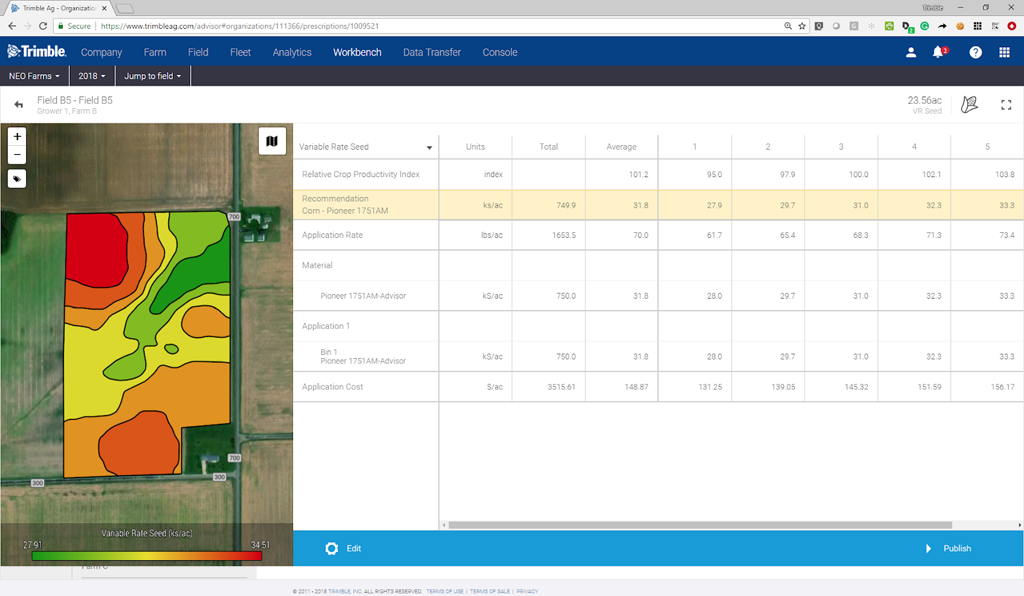

Advisor Prime

Advisor Prime is Trimble’s intelligent, fully integrated web-based solution featuring streamlined workflows for creating and sharing management zones and variable rate prescriptions. By using Advisor Prime, you’ll reduce data entry errors created by repetitive field-by-field procedures, cut out hours of processing time, and eliminate steps in transferring data back to the farmer.

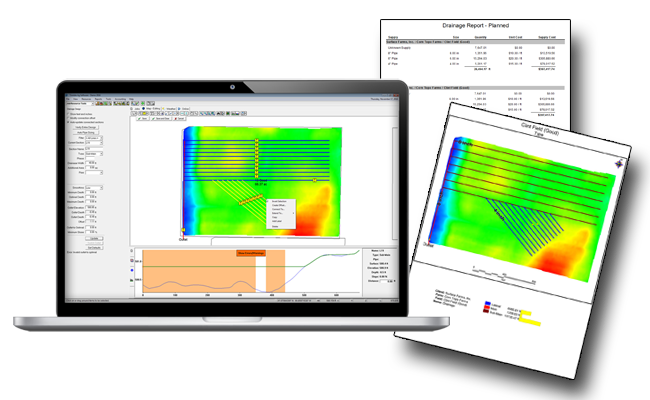

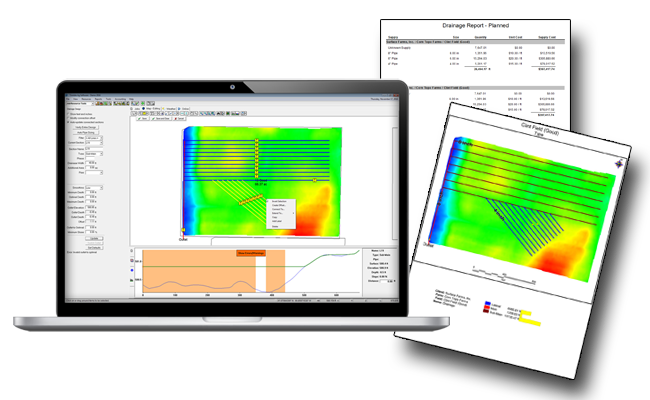

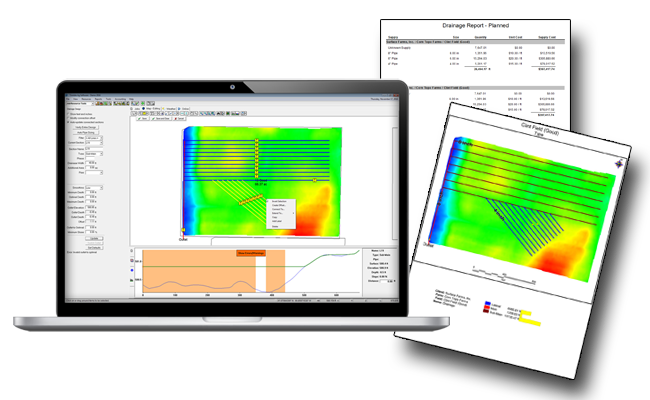

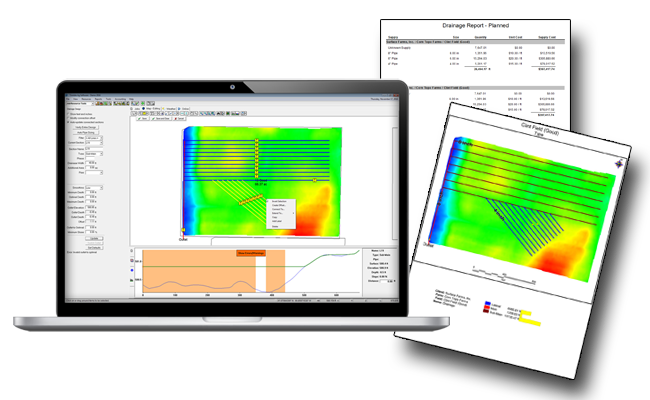

WM-Subsurface

WM-Subsurface (formerly known as Farm Works Surface) is farm drainage software that works with the Trimble® WM-Drain™ farm drainage solution. WM-Subsurface ensures the optimal placement of tile and surface drains in both surface and sub-surface drainage water management projects, helping to drain fields adequately and increase crop yields. Easily overlay other layers such as yield or soil types to help visualize the field from different perspectives.

Field-IQ Crop input control system

The Trimble® Field-IQ™ crop input control system enables productive and efficient functionality for your planting and nutrient and pest management operations. The Field-IQ system works with the Trimble TMX-2050 display and CFX-750™ display.

Variable Rate Application Control

Save on input costs by monitoring and simultaneously varying up to 6 different materials to precisely plant seeds, apply chemicals, and broadcast fertilizers. -Keep as-applied mapping records of inputs -Adjust your seed population, fertilizer rates, or spray application manually or using a prescription created with Trimble Ag Software

Automatic Section Control

Increase your profits by avoiding double coverage and eliminating wasted inputs using automatic or manual section control. -Automatically control up to 48 rows individually for maximum savings and increased yields -See where you have been and what you have done with overlap detection -Eliminate overlap by adding Tru Count Air Clutches® and Tru Count LiquiBlock™ Valves

Tru Count Products

Tru Count Air Clutches and LiquiBlock valves deliver superior performance for all your planting and spraying applications. They allow you to start and stop the flow of seed and fertilizer in real-time from the vehicle cab. With almost instant activation or deactivation, there is no lag time in your operation.

Seed Monitoring

Monitor real-time seeding information or fertilizer delivery lines and prevent costly planter problems by catching them early before they cause yield reduction. -See the results of singulation analysis, including information on population, singulation, skips/multiples, spacing, and quality of spacing

Field-IQ ISOBUS Control System

The Trimble® Field-IQ ISOBUS control system is an ISO-compatible application control system that can be used on any implement applying a product for an operation. Combining the modular Field-IQ architecture with the new Trimble Control ECU, making rate and section control solutions available.

Field-IQ ISO Weather Station

The Trimble ISOBUS Weather Station informs you of instantaneous changes in the weather and is available via the easy-to-use ISO Universal Terminal (UT) interface. Wind speed and direction are measured using four ultrasonic transducers. No moving parts translates to better durability and reliability.

WeedSeeker 2 Spot Spray System

WeedSeeker® 2 is the next generation spot spray system from Trimble Agriculture. Redesigned for superior weed killing, it delivers all-around improved performance to previous solutions. Using advanced optics and processing power, the WeedSeeker system detects and eliminates resistant weeds. When a weed passes underneath the sensor it signals its linked spray nozzle to precisely deliver herbicide and kill the weed, reducing the amount of chemical applied by up to 90%.

GreenSeeker System

The Trimble® GreenSeeker® crop sensing system helps you effectively and precisely manage crop inputs on-the-go. With GreenSeeker, you can address field variability by applying the right amount of fertilizer, in the right place, at the right time. -Create a high-yielding environment for your crop to grow -Reduce nutrient input costs by eliminating excess application -Eliminate the need for application maps or agronomist recommendations -Operate night or day, and in fog or clouds

Yield Monitoring

With Yield Monitoring, you can map and compare the performance of different seed varieties throughout your field, and improve seed selection based on yield data over multiple years.

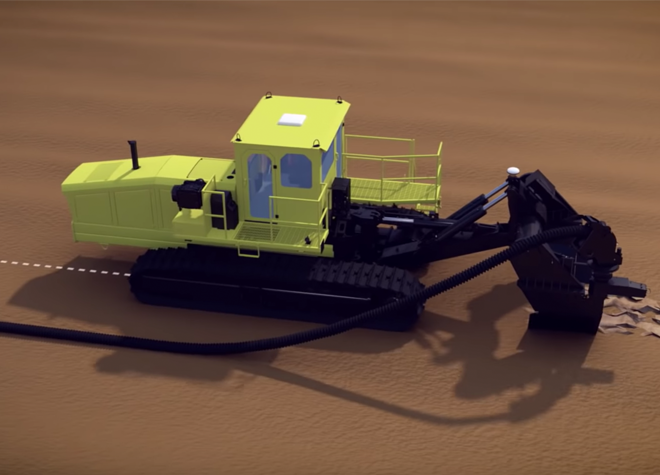

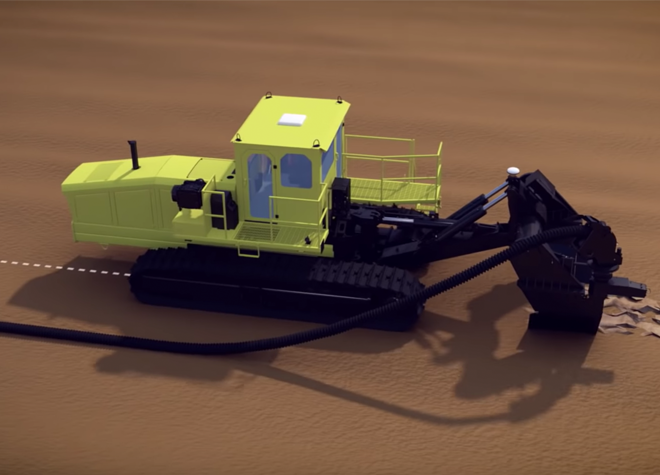

WM-Drain Farm Drainage Solution

The Trimble® WM-Drain® farm drainage solution is a concept-to-completion toolset that streamlines the survey, analysis, design, installation, and mapping steps of surface and subsurface drainage. The WM-Drain solution ensures optimal 3D drain placement, which improves crop yields by controlling ponding, optimizing root depth, maximizing planting seasons, and minimizing nutrient loss.

WM-Subsurface

WM-Subsurface (formerly known as Farm Works Surface) is farm drainage software that works with the Trimble® WM-Drain™ farm drainage solution. WM-Subsurface ensures the optimal placement of tile and surface drains in both surface and sub-surface drainage water management projects, helping to drain fields adequately and increase crop yields. Easily overlay other layers such as yield or soil types to help visualize the field from different perspectives.

Trimble® FieldLevel™ II system

he Trimble® FieldLevel™ II system streamlines the surveying, designing, and leveling steps required for land leveling projects. It also provides two methods for installing rice levees. FieldLevel II helps ensure optimal water management by providing improvements in yields, water usage, and farm productivity.

WM-Form Land Forming Solution

Whether you’re a grower or an earthworks contractor, the Trimble® WM-Form™ land forming solution can help you fix under producing acres – while also controlling the cost of the earthworks and minimizing disturbance to valuable topsoil.

SNM941 Connected Site Gateway

The SNM941 is like a dedicated hotline sending and receiving vital information from the field – design updates, GNSS corrections, production information, and even tech support.

Auto Asset Detection

Automatically switches implement profiles when the implement is changed.

Trimble Protected Plus+

A Trimble Protected Plus+ plan protects against standard wear and tear, environmental damage and surge protection. A Plus+ plan helps you avoid those unexpected and unbudgeted repair costs which could shut your operations down. This Hardware-only and select system coverage plan provides many features including no additional charges for eligible warranty repairs, protection against standard wear and tear, environmental damage, and surge protection. It comes with a transferable ownership (plan follows serial number) which will make your equipment more valuable if you ever decide to sell it.

Trimble Protected Plus+ with Rapid Replace

All products are available for Rapid Replace plans; some products can’t be repaired in the field due to the type of product technology. A Plus+ Plan with Rapid Replace allows your Distributor to swap out the non-functioning equipment with a replacement. Rapid Replace is available during the Factory Warranty! The replacement product comes with the remainder period of the original protection plan. It is a simple and an easy way to get back up and running quickly.

Trimble Protected Plus+ Reinstate

Reinstatement of warranty is available for hardware that is no longer protected under factory warranty.

Promotions X

Mussum Ipsum, cacilds vidis litro abertis. Praesent vel viverra nisi. Mauris aliquet nunc non turpis scelerisque, eget. A ordem dos tratores não altera o pão duris. Casamentiss faiz malandris se pirulitá. Si num tem leite então bota uma pinga aí cumpadi!

Apply Here for Financing

Apply Here

GFX-1260™ Display

GFX-1060 display

GFX-750™ Display

Learn More

GFX-350™ Display

Learn More

TMX-2050™ Display System

Learn More

NAV-900 Guidance Controller

Learn More

NAV-500™ Guidance Controller

Learn More

Autopilot™ Automated Steering System

Learn More

Autopilot™ Motor Drive System

Learn More

EZ-Pilot® Pro Guidance System

Learn More

EZ-Pilot® Assisted Steering System

Learn More

EZ-Steer® Assisted Steering System

Learn More

TrueTracker Implement Steering System

Learn More

TrueGuide Implement Guidance System

Learn More

RG-100 Row Guidance

Learn More

VerticalPoint RTK™ Grade Control

Learn More

CenterPoint® RTK

Learn More

CenterPoint® VRS

Learn More

Trimble xFill

Learn More

CenterPoint® RTX

Learn More

RangePoint® RTX

Learn More

OmniSTAR

Learn More

ViewPoint® RTX

Learn More

WAAS/EGNOS/MSAS

Farmer Starter

Learn More

Farmer Core

Learn More

Farmer Pro

Learn More

Ag Premium Weather

Learn More

Ag Time Tracker

Learn More

Advisor Prime

Learn More

WM-Subsurface

Learn More

Field-IQ Crop input control system

Learn More

Variable Rate Application Control

Learn More

Automatic Section Control

Learn More

Tru Count Products

Learn More

Seed Monitoring

Learn More

Field-IQ ISOBUS Control System

Learn More

Field-IQ ISO Weather Station

Learn More

WeedSeeker 2 Spot Spray System

Learn More

GreenSeeker System

Learn More

Yield Monitoring

Learn More

WM-Drain Farm Drainage Solution

Learn More

WM-Subsurface

Learn More

Trimble® FieldLevel™ II system

Learn More

WM-Form Land Forming Solution

Learn More

Trimble Protected Plus+

Learn More

Trimble Protected Plus+ with Rapid Replace

Learn More

Trimble Protected Plus+ Reinstate

Learn More

Fully Automated

With Sabanto Ag's Aftermarket Platform Kit for the Kubota M5-091 and M5-111, these tractors will be available 24/7 to complete field and event missions while you are free to do whatever you want while it completes all of your day to day tasks, or grab another cup of coffee.

Sealed Tank

Tank is sealed to maintain air pressure between bins for greater row to row accuracy. Simple yet rugged designed tank & lid seal, using automotive rubber gasket.

High quality injection molded HDPE plastic augers

Very accurate metering with large rate range (25lbs. – 500lbs. per tank). See capacity chart for details. No need to change metering drive for full rate range – unlike other competing brands.

Food Grade Stainless Steel and Poly Construction

Long life, cleans up easy

Single Hydraulic Input Requirement

Reduces hydraulic requirements allowing for more options for grower

The 2208 has two options for PWM Hydraulic Block, a Single or a Dual product.

The Montag specific hydraulic block allows for industry leading control of the product metering system and the fan with only one hydraulic bank required. The block includes safety valves to protect the fan seals and reduces heat in the hydraulic system.

Tank Ladder access

Safe entry and exit. Easy access for clean out.

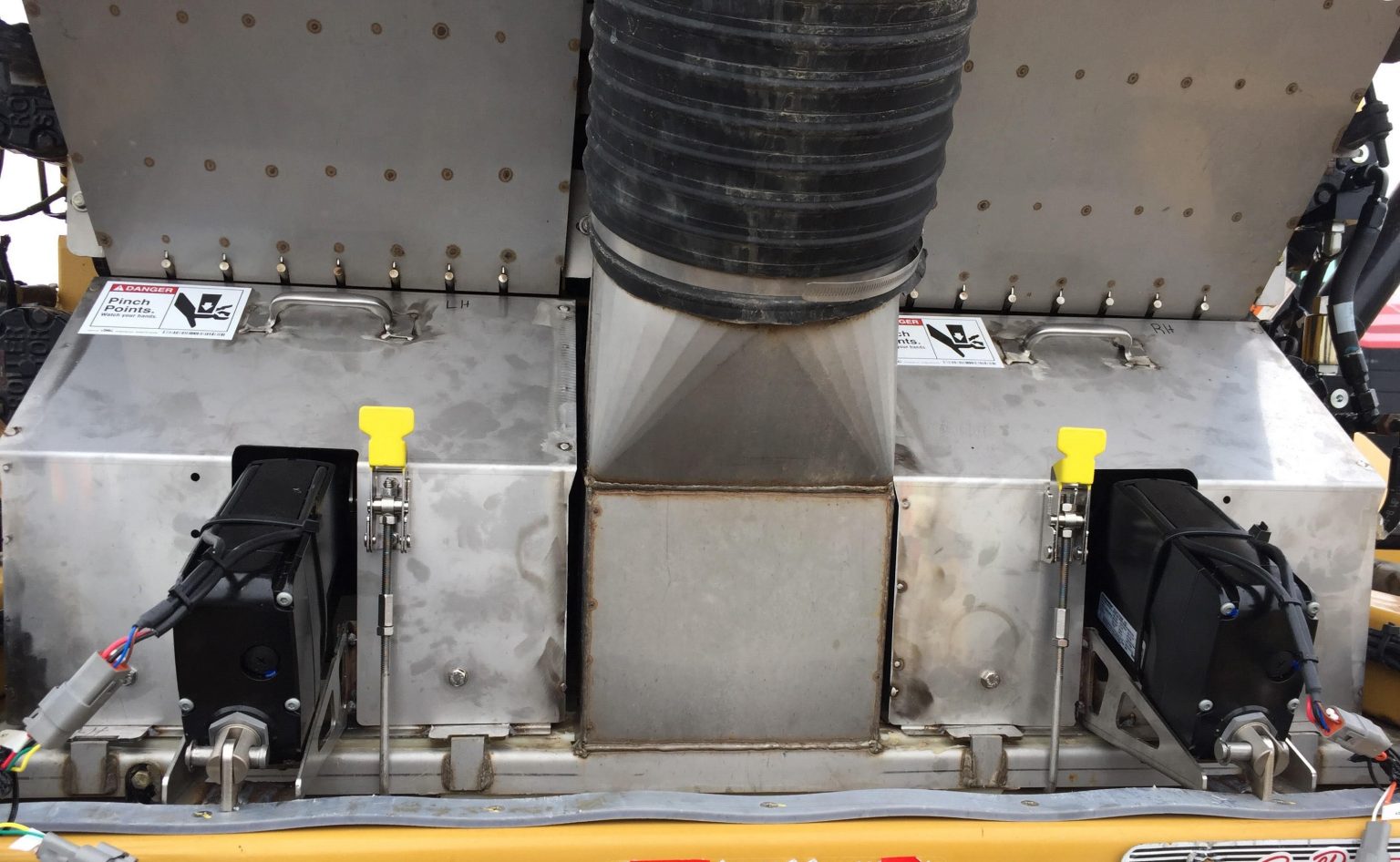

Improved Montag Fluid Bed – 2208 Air Delivery System

2208 air system is streamlined to improve aerodynamics and reduce horsepower requirements Fertilizer is introduced into the air stream at the air chamber requiring less pressure to move it to the row unit

Components are corrosion resistant

Any component that comes in direct contact with fertilizer is either stainless steel or plastic. Components outside the tank (such as Valves / Weigh bars / Elec. Harnessing) are all selected with our corrosive environment in mind for in field reliability.

Up to 4 section configurations

-Sections can be added to the 2208 system at any time – giving you added flexibility. -Sections are controlled with hydraulic motors and PWM valves for infield reliability.

Configurable Rows

Rows can be added and subtracted to fit your farming operation’s needs.

Tank Design

-Functional yet streamlined in its design. -Integrated twist-lock lid.

Screen Design

-Screens are integrated into the tank to removes large materials when loading that can plug down tubes or can harm metering system. -One ¾” screen per tank is provided.

Metering Discharge Outlets

Outlets can be turned to blow either forward or backwards by turning the air chamber pan, this allows the grower to choose the direction the fan and outlets are positioned depending on the application needed.

2208 at the 2019 Farm Progress Show

Watch Brian Johnson, Sales manager for Montag Manufacturing, talk about the Gen II 2208 at the 2019 Farm Progress show.

High quality injection molded HDPE plastic augers

Very accurate metering with large rate range (25lbs. – 500lbs. per tank). See capacity chart for details. No need to change metering drive for full rate range – unlike other competing brands.

Food Grade Stainless Steel Trough and Poly Tank Construction

Long life, cleans up easy

Single Hydraulic Input requirement

Reduces hydraulic requirements allowing for more options for grower

PWM Hydraulic Block Standard

The Montag specific hydraulic block allows for industry leading control of the product metering system and the fan with only one hydraulic bank required. The block includes safety valves to protect the fan seals and reduces heat in the hydraulic system.

Sealed Tank

-Tank is sealed to maintain air pressure between bins for greater row to row accuracy. -Simple yet rugged designed tank & lid seal, using automotive rubber gasket.

ISOBUS Rate Controller

Specifically developed to operate GEN II system with full functionality. Compatible with most of the industries displays – Contact Montag representative for more information.

ISOBUS Scale

GEN II’s come standard with each tank being mounted to the frame with an ISOBUS scale. ISOBUS scales are integrated into the GEN II Montag rate controller.

Tank Ladder Access

-The rear deck can be configured for the ladder to be mounted for a left or a right-hand entrance. -Additionally, ladder can be ordered with a rear access.

Improved Montag Fluid Bed – GEN II Air Delivery System

-GEN II air system is streamlined to improve aerodynamics and reduce horsepower requirements. -Fertilizer is introduced into the air stream at the air chamber, requiring less pressure to move it to the row unit.

Components are corrosion resistant

-Any component that comes in direct contact with fertilizer is either stainless steel or plastic. -Components outside the tank (such as Valves / Weigh bars / Elec. Harnessing) are all selected with our corrosive environment in mind for in-field reliability.

Up to 4 section configurations

Sections can be added to the GEN II system at any time – giving you added flexibility. Sections are controlled with hydraulic motors and PWM valves for infield reliability.

Configurable Rows

Rows can be added and subtracted to fit your farming operations needs.

Tank Design

The GEN II comes with two 4.5-ton (US) tanks with a built-in walk way that divides the tanks and built-in steps for accessing the inside of the tank.

Screen Design

-Screens are positioned with a 7-degree angle to help fully fill the tank by driving the fertilizer to the outside of the tank when filling. -2018 GEN II’s and newer will include a full set of (2) ½” screens and (4) ¾” screens. -Removes large materials when loading that can plug down tubes or can harm metering system.

GEN II Product Release

Watch Roger Montag, Presedent of Montag Manufacturing, talk about the Gen II

High quality injection molded HDPE plastic augers

-Very accurate metering with large rate range (25lbs. – 500lbs. per tank). See capacity chart for details. -No need to change metering drive for full rate range – unlike other competing brands.

Food Grade Stainless Steel and Poly Construction

Long life, cleans up easy

Single Hydraulic Input Requirement

Reduces hydraulic requirements allowing for more options for grower

PWM Block with fan protection

The Montag specific hydraulic block allows for industry leading control of the product metering system and the fan with only one hydraulic SCV required. The block includes safety valves to protect the fan seals and reduces heat in the hydraulic system.

Sealed Tank

-Tank is sealed to maintain air pressure between bins for greater row to row accuracy. -Simple yet rugged designed tank & lid seal, using automotive rubber gasket.

Tank Ladder access

-Safe entry and exit. -Easy access for filling and clean out.

Improved Montag Fluid Bed – 2108 Air Delivery System

2108 air system is streamlined to improve aerodynamics and reduce horsepower requirements. Fertilizer is introduced into the air stream at the air chamber requiring less pressure to move it to the row unit.

Components are corrosion resistant

-Any component that comes in direct contact with fertilizer is either stainless steel or plastic. -Components outside the tank (such as Valves / Weigh bars / Elec. Harnessing) are all selected with our corrosive environment in mind for in field reliability.

Up to 4 section configurations

-Sections can be added to the 2208 system at any time – giving you added flexibility. -Sections are controlled with hydraulic motors and PWM valves for infield reliability.

Configurable Rows

-Rows can be added and subtracted to fit your farming operation’s needs.

Tank Design

-Functional yet streamlined in its design. Allows for the tank to be both light weight yet rugged and durable for years to come. -Integrated twist-lock lid.

Screen Design

-Screens are integrated into the tank to removes large materials when loading that can plug down tubes or can harm metering system. -One ¾” screen is provided with the meter.

Metering Discharge Outlets

-Outlets can be turned to blow either forward or backwards by turning the air chamber pan, this allows the grower to choose the direction the fan and outlets are positioned depending on the application needed.

Crary Fan

Industry standard for quality, high performance with low hydraulic requirements.

Dwyer Air Gauge

Accurate fan pressure reading with magnetic mount.

Mechanical slide gate control

Allows user to segregate the product from the metering augers, easier cleanout, maintenance or when roading.

3-year Warranty

High quality, for customer satisfaction and confidence.

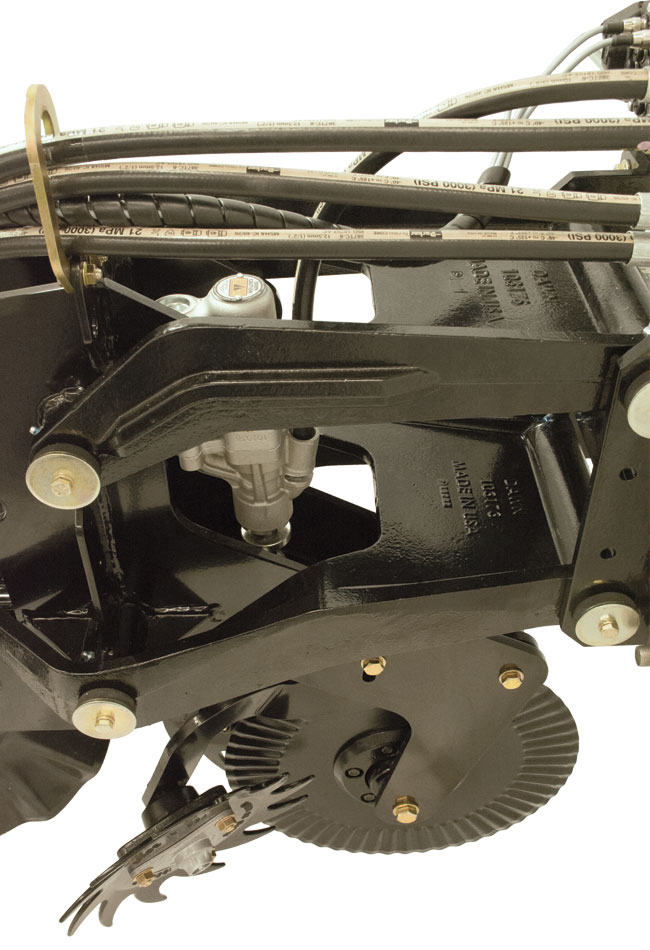

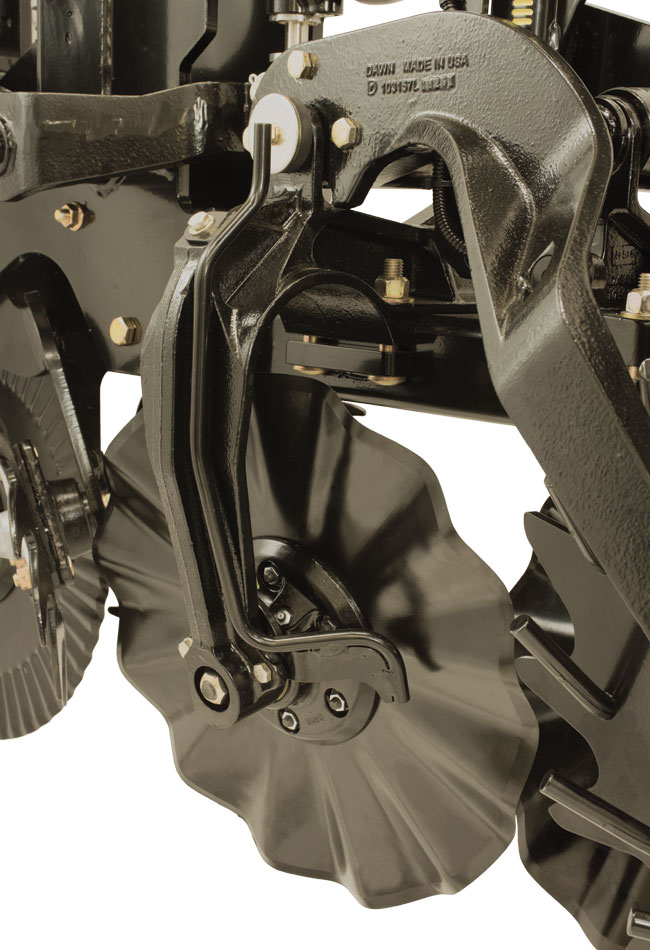

Dawn Black One

Dawn Black One is a complete pull-type strip-till toolbar and fertilizer delivery system. It features a 9 ton integrated fertilizer cart.

Stainless Fertilizer Delivery

Stainless Steel tubes are mounted directly over top of the toolbar, and terminate at each row for clean and effective fertilizer routing.

Reduced Transport Height

The Black Dawn One toolbar uniquely packages the axle assembly, and keeps all the primary structure low. This reduces transport height

Integrated cat walk

Another unique feature is the visual indicator for tongue height. The cat walk allows easy access to the fertilizer hopper.

Full Motion of hose routing.

Solving one of the common problems with dry fertilizer systems on pull type toolbars, the motion of hoses folding and unfolding is controlled.

Integrated Fertilizer Chute

The fertilizer chute makes removing unused fertilizer a simple task. Notice the fertilizer tubes suspended near the pivot on a support arm for easy folding.

Active Wing Transfer

Black Dawn One was designed, from day one, to include hydraulic wing weight transfer. A critical element for consistent performance across all rows.

Improved Ground Clearance

Ground clearance can be a real challenge in some conditions. The Black Dawn One has enough to accommodate almost any tough terrain.

Black Dawn One Field Demo

The 16 row should be coupled with a tractor between 250 hp at the low end and 450 hp at the high end. Pulling this bar 10 mph will require 350-400 hp in most cases

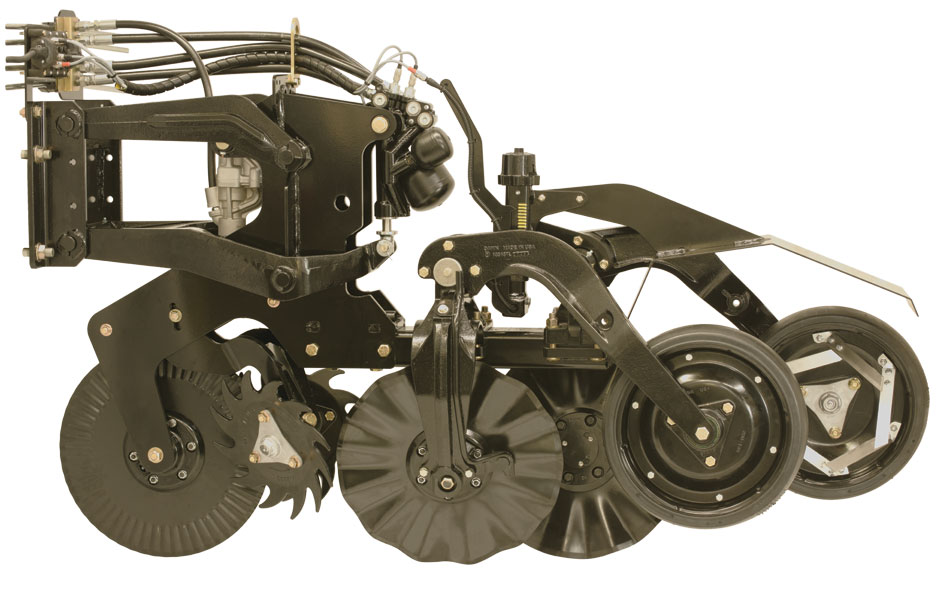

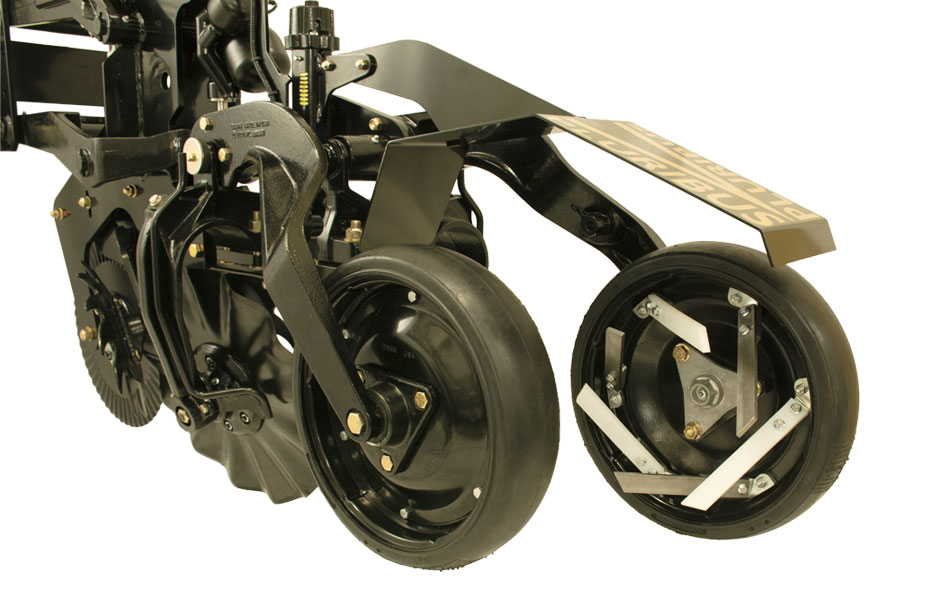

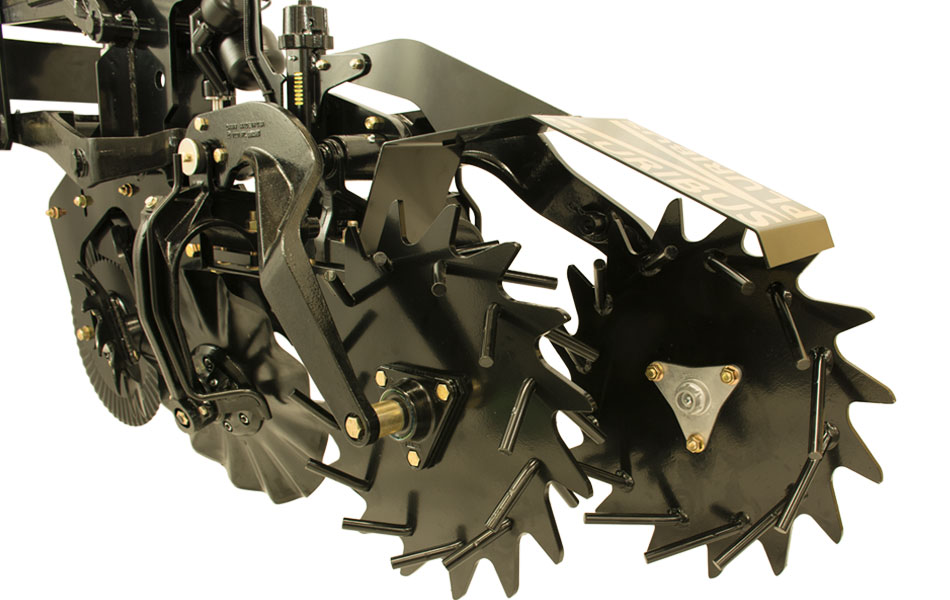

Pluribus V

The Pluribus V features Rfx+ row-by-row, automated hydraulic down-force. The system utilizes a strain gauge sensor paired with our new easy screw-adjust depth control. The 3333 will maintain accurate down pressure for any change in soil conditions.

Quick and Effortless Adjustments

A simple acme screw adjust system lets you quickly, and easily set depth on walking tandem gauge wheels. A load cell is located in the stop on the tandem, and gives feedback to the microcontroller that is regulating the hydraulic suspension system. A bracket runs up from the stop to support the load cell cable, and it doubles as a depth indicator by pointing to the yellow graduations marked out on the depth adjustment mount.

In-cab Control of Row Cleaners

Row crop residue varies as you move through the field. The Pluribus V gives you complete, immediate in-cab control over your integral GFX hydraulic, floating row cleaners. A simple dial controls the GFX cylinders, and allows you to keep moving while making row cleaner adjustments.

Swirl Gauge Wheels

The standard gauge wheel on the Pluribus V is a heavy-duty rubber wheel and hub. The gauge wheel is equipped with the Dawn Swirl finishing tool. Alternating steel and plastic tines aggressively chop at the soil as it leaves the central coulters. It further crumbles clods, and leaves a 1.5"-2" berm about 8"-10" wide as a seed-bed

Optional Tine Wheel

Alternative to the standard wheels, we offer a toothed wheel with lateral pulverizers. It chips away at side wall compaction, similar to the Dawn Curvetine, and breaks down clods.

Guage Wheel difference's

Here, the right two rows have the metal basket wheel and the left rows have the rubber wheels with the swirls. The metal basket wheels have teeth that scarf the edge of the strip where the tilled area meets the untilled area. The metal wheels tend to be more effective at breaking up clods in very heavy clay soil types

Liquid Fertilizer Option

Detail view of the liquid fertilizer tubes that can be added to one or both sides of the row. These tubes will produce an approximate 3 x 3 placement relative to the center of the row

Pluribus V Strip Till Gets uplift with Reflex Down Pressure Control

When you are trying to strip till in the spring depth control is everything. The Pluribus V Strip Till row unit is getting uplift and the industry leading Reflex down pressure control system, which allows it to float over wet spots.

Standard 6' Pull-type Plow

-Built to the highest standards, the Liebrecht Tile Plow works in the harshest conditions -Cantilever action with a 10′ bottom for unsurpassed grade control -Tandem axle available for minimal ground disturbance -Capable of laying up to 10″ tile 6′ deep for Standard Tile Plow (7′ Model Available) -Tail sections of tile boot forms groove for proper tile support -Powder coat for durable, high quality finish

Superior Construction

-Construct waterways in 1/4 of the time of conventional methods -Reduce compaction, fuel, and labor costs -Construct or maintain surface drains and grass waterways of any shape or size -Handles varying types of soils with ease; performs in rock and other heavy debris -Trimble WM Drain GPS or Laser grade automation for the most accurate grade control on the market -Capable of moving 10-12 yards of dirt per minute -Directional discharge control with the ability to windrow the material close to the machine or throw it out as far as 120 feet -All wear parts are replaceable -Independent side blades for sloping waterways and surface drains -Automatic self-leveling tilt to keep machine level in uneven conditions -Truck Loading Hood optional -Enables easy removal of pulverized ready to spread dirt -Mounted Waterway Ditchers available in 5′ and 6′ models -Side blades and adjustable hood are standard equipment -Quick hitch standard on all mounted Ditchers

Gradable Box

-Construct waterways in 1/4 of the time of conventional methods -Reduce compaction, fuel, and labor costs -Construct or maintain surface drains and grass waterways of any shape or size -Handles varying types of soils with ease; performs in rock and other heavy debris Trimble WM Drain GPS or Laser grade automation for the most accurate grade control on the market -Capable of moving 10-12 yards of dirt per minute -Directional discharge control with the ability to windrow the material close to the machine or throw it out as far as 120 feet -All wear parts are replaceable -Independent side blades for sloping waterways and surface drains -Automatic self-leveling tilt to keep machine level in uneven conditions -Truck Loading Hood optional -Enables easy removal of pulverized ready to spread dirt -Mounted Waterway Ditchers available in 5′ and 6′ models -Side blades and adjustable hood are standard equipment -Quick hitch standard on all mounted Ditchers

Side Arm Ditcher

-Varied sized heads to match ditch size (3ft to 5ft diameter) -Reaches depths of 0-10ft model dependent -Hydraulically driven head for optimal performance -Trimble WM Drain GPS or Laser grade automatic control available -Automatic tilt compensation -Built to customer specifications -Two-point, pull-type and truck mounted units available

Tile Trailer

-Table made to accommodate any size maxi coil -Standard LED brake lights for easy transport -Operates on tractor hydraulics or optional self-contained hydraulic unit with remote cable -Extra spools available -Three Point Tile Trailer also available -Powder coated for durable, high quality finish

Laser Tower

Quick laser setup and stability, even in windy conditions

Standard Control

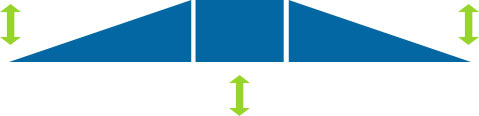

Basic, low cost height control solution for smaller booms (up to 90′). Ideal for mild, flatter terrain. Automatically and independently controls main lift height while utilizing existing on/off valves to independently control each of the wings, producing an ideal, pre-set height above the ground or crop.

Passive Roll

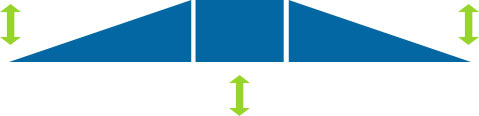

Advanced, most popular height control solution offered for nearly all sprayer models on the market. Fully capable in challenging terrain. Automatically and independently controls main lift while utilizing NORAC Proportional Valves to independently control each wing, producing an ideal and consistent pre-set height above the ground or crop.

Active Roll

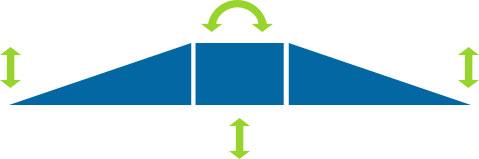

Premier height control solution designed for all boom sizes. Developed for inconsistent, challenging terrain. Automatically and independently controls main lift while utilizing NORAC Proportional Valves to ensure smooth independent control of each wing. Monitors, measures and controls boom center section roll to maintain an ideal, pre-set height above the ground or crop.

Active Wing Roll

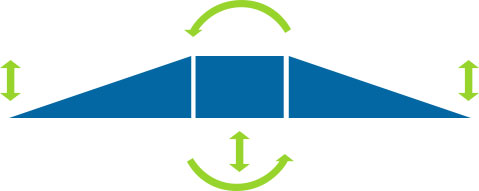

Premier height control solution designed for all boom sizes, offered for nearly all sprayer models on the market. Developed for inconsistent, challenging terrain. Automatically and independently controls main lift while utilizing NORAC Proportional Valves to ensure smooth independent control of each wing. Hydraulically links the left and right wings to simulate roll without manipulating the center section to maintain an ideal, pre-set height above the ground or crop.

NORAC Boom Height Comparison

See NORAC out-perform the competition in this comparison video.

UC7™ Premier Boom Height Control System

Premier boom height control system. ISOBUS 11783 certified, the UC7 system can be operated through any Universal Terminal. Alternatively, it can be used as a stand-alone system that is operated through the NORAC PULSE™ color touchscreen display. The UC7 system is not only easy to operate, but offers cutting-edge troubleshooting and diagnostic capabilities.

UC5™ Advanced Boom Height Control System

Advanced boom height control system. ISOBUS 11783 certified, the UC5 system can be operated through any Universal Terminal. Alternatively, it can be used as a stand-alone system that is operated through the NORAC PULSE™ color touchscreen display. The UC5 system is not only easy to operate, but offers advanced troubleshooting and diagnostic capabilities.

UC4.5™ Entry Level Stand-Alone Boom Height Control System

Entry level stand-alone boom height control system. Using CANbus communication, this entry level system comes complete with a stand-alone eight digit display, but is not Universal Terminal compatible.

Universal Terminal (UT) Compatibility

NORAC control systems are ISOBUS 11783 certified.

Ultrasonic Sensor

The initial concept of NORAC’s Ultrasonic Sensor was developed more than 15 years ago and has cultivated into a leading technology of high precision. NORAC Ultrasonic Sensors are easy to configure, microprocessor based and temperature compensated. They also featuring advanced clarity, reporting the top of the crop, soil, and multiple levels in between simultaneously. This is useful in applications where the crop height and other agronomic data is of interest such as prescription mapping, real time variable rate, crop measurement, and crop mapping. The readings can be used in conjunction with NORAC’s patented Hybrid Mode™ algorithms, which use a “virtual top of crop” to add stability for a variety of control applications.

Rugged Brackets

Breakaway or low profile brackets are used to mount the ultrasonic sensors to the boom. Breakaway bracket will pivot to avoid damage from boom strikes, while low profile brackets are useful in situations where the breakaway bracket will not fit on the boom and also has a rain flap option to protect the sensor when the boom is folded.

Proportional Valves

A separate NORAC-designed proportional valve is used for each wing to ensure smooth independent hydraulic control. NORAC proportional valves offer automatic oil temperature monitoring and compensation for superior performance.

Active Control™ Technologies

The addition of an Active Control™ Technology enables the sprayer to go over severe terrain by actively rolling the center section or simulating roll in the center section, as well as controlling wing lift. Spray height is maintained, even in the most severe conditions.

Roll Sensors and Position Sensors

Various roll sensing technologies are used to measure boom dynamics. This enables the system to predict the effects of center section and chassis roll on boom height and compensate for it. The technology manages boom stability by preventing one boom’s action from affecting the other and allows the boom roll suspension to perform as designed without interference.

Hybrid Mode™

Hybrid Mode™ provides the operator with a level of performance not provided from other height controllers on the market. It is most useful when spraying in-crop and when there are difficult conditions such as washed out areas, thin or lodged crop, or wheel tracks. The result is stable and reliable height control in all crop conditions. Unlike any other solution on the market, Hybrid Mode™ combines the function provided by the two operating modes, Soil Mode™ and Crop Mode™ by tracking both the soil surface and crop canopy simultaneously. If the crop canopy is not continuous, Hybrid Mode™ will track the soil surface and determine a continuous “virtual” crop canopy as an operator would expect in these crop conditions.

MAX Sensing™

Max Sensing™ offers a new way to measure boom dynamics and has made boom height control smarter, and more intuitive. Able to adapt to almost any boom design, MAX Sensing is especially important for boom height control performance on rigid booms and other booms that are challenging to control. Available for select UC5™ Passive Roll™ and Active Wing Roll™ systems.

YOU CAN ONLY REAP WHAT YOU SOW

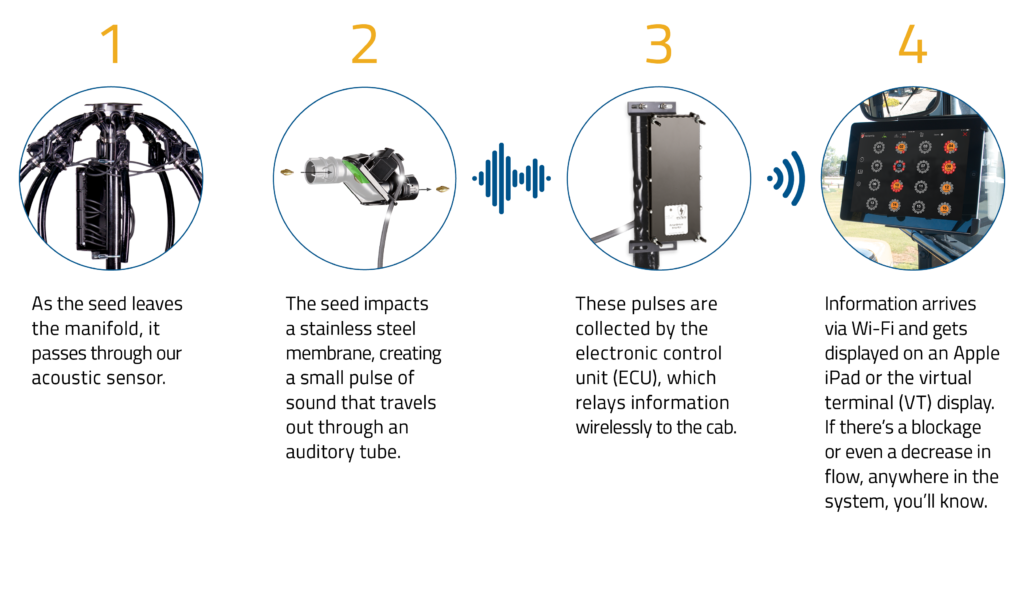

The Recon Wireless Blockage and Flow Monitor provides reliable, versatile machine monitoring technology to improve precision in every pass. Unlike traditional optical sensors, our patented acoustic sensors monitor the sound of the seed flow so you can depend on accurate readings even if the sensors get dusty. The system is easy-to-install and can adapt to nearly any brand of equipment for a variety of applications. Its software is compatible with your iPad to provide a simple, user-friendly interface that displays all manifold runs and gives you an audible alert if a run becomes blocked.

How it Works

Say goodbye to dust-covered optical sensors. The acoustic sensors in your Recon Wireless Blockage and Flow Monitor function like a stethoscope, instantly detecting blockages or reduced seed flow, anywhere on the implement.

Machine Compatibility

Multiple sensor options allow the system to easily adapt to nearly any rig or application: Bourgault, Case IH, John Deere, Seed Hawk, Amity, Sunflower, Horsch, Flexi-Coil and more Multiple Product Types and Rates Dry Fertilizer Applicators, Deep Banders, and Strip-Till Units Dual-Shooting and Mid-Row Banders

ACCURATE APPLICATION FOR YOUR FIELDS

Recon SpreadSense® is the industry’s first blockage monitor for floaters. Stand out with the latest technology to ensure the most accurate application for your customers. Utilizing the same acoustic technology developed for other Recon monitoring systems, Recon SpreadSense provides reliable real-time blockage detection.

Sound Investment in Smart Farming

Eliminate misapplication claims and customer complaints with Recon SpreadSense. Our system costs pennies per acre and can save farmers thousands per field. Fertilizer misapplication resulting from one plugged tube (2 deflectors) on a broadcast boom over a 160-acre field can cost the farmer a lost revenue of $4,000 in corn, $3,000 in soybean, and $1,650 in wheat. Now that's a sound investment. *Based on a 70 ft boom and 50% yield reduction in areas of the field where fertilizer is misapplied.

Benefits

REDUCE OPERATOR STRESS Ensure accurate distribution of products across your floater and increase your efficiency by not having to visually detect flow issues so you can improve the effectiveness of the applicator. ELIMINATE MISAPPLICATION CLAIMS A blocked run can cost thousands of dollars in insurance claims. Reduce the risk of misapplied product and customer complaints with reliable blockage monitoring. TRUSTED TECHNOLOGY WITH PROVEN PERFORMANCE Monitor machine performance to ensure optimal application. Identify other issues affecting your floater. With Recon SpreadSense you can measure individual deflector flow status and relative flow across the entire boom. EASY TO INSTALL The acoustic sensors are easy to install on the back of each deflector which doesn’t cause any disruption to product flow.

How it Works

Our acoustic sensor technology provides reliable, real-time flow detection. The acoustic sensors are easy to install on the back of each deflector to listen for material flow and send sound pulses through auditory tubes, similar to a stethoscope. The data is collected by an Electronic Control Unit (ECU), which displays the information on an iPad® in the cab. If there’s a blockage anywhere in the system, you’ll know.

SECTION CONTROL FOR DRY FERTILIZER APPLICATORS

Shouldn’t your fertilizer application have more precision too? Tractors can now steer themselves, seeds can be planted with 98% accuracy, prescription mapping allows for variable rate population and nutrient control, and section control and individual row-unit control allows for inputs to be precisely placed. Get advanced section control for your floater, and reduce the width of swath control from 35 feet to 17.5 feet. Double the number of sections you can control (from two to four sections).

Benifits

-Important tool to more accurately and sustainably apply fertilizer. -Reduce fertilizer application overlap in irregularly shaped fields, fields with sloughs and wetlands, and fields with center pivot irrigation systems. -Reduce the environmental impact of double fertilizer application rates by reducing overlap areas. -Maximize the effectiveness of prescription tools commonly used in precision agriculture applications with the ability to control fertilizer application rates over smaller areas. -Maximize farm profits by reducing fertilizer overlap and improving the distribution of fertilizer.

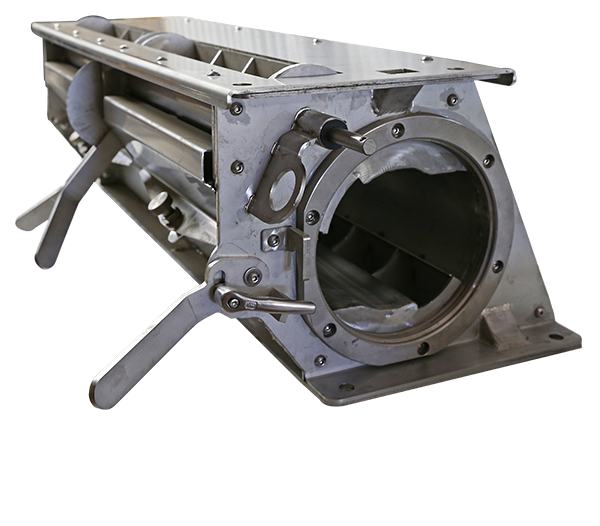

REDUCE OVERLAP. DECREASE INPUT COSTS.

Enhance your precision seeding capabilities with Intelligent Ag’s Engage® Zone Control. We designed and built Engage Zone Control to add input-reducing section control to your John Deere 1910 air cart. Our system communicates with the existing GPS mapping system to ensure that every seed is in its place. With its ability to open and close up to eight sections per bin, the Engage Zone Control system prevents over-seeding to help maximize your profit margins. Like all our products, it’s built to last. Engage Zone Control is truly a simple economical solution to enhance your equipment’s efficiency.

Sound Investment in Smart Farming

Our system can pay for itself in the first season. In today’s competitive and uncertain market, maximizing margins is vital to improving your profit potential. With so many factors affecting your yields, you can’t control what you get out of every acre. But you can control what you put in. You can add the latest precision seeding technology to your air cart, and our system can pay for itself in the first season. That’s a sound investment for smarter farming. Our customers reported an average of 7% savings on input costs.

Benifits

Field-tested and simple to use, the Engage® Zone Control system shuts off between one and eight sections per tank, for up to three tanks. DURABLE Built with corrosion-resistant stainless steel. EASY TO MAINTAIN AND SERVICE Features an electronic system for easy maintenance – no hydraulics. RELIABLE Developed by Intelligent Ag – the same team who brought you innovative solutions for existing iron, like the Recon Wireless Blockage and Flow Monitor.

Features

- Stainless steel end plates and shut offs. - Minimal plastic. - Built for durability and longevity. - Added clean out plate for easy end of season maintenance.

Compatibility

- Case, Flexicoil & New Holland. - John Deere 1900 & 1910 ground drive. - John Deere hydraulic drive meter housings. COMING SOON! - Morris 6000, 7000, 8000 series meter housings. COMING SOON!

Above the Meter Housing (Single & Double Chute)

- SS Lower Ladder Bracket Funnel. - Ladder Funnel Seal. - SS Top Meter Mounting plate. - Top Meter Seal. - SS Upper Hardware Kit.

Below the Meter Housing

- SS Manifold Bracket, Single Chute. - SS Manifold Bracket, Double Chute. - SS Manifold Side Plate, Single Chute (2 required per meter). - SS Slide Stop Bracket, LH, RH, Double Chute. - SS Bottom Clean-out Plate, Single & Double Chute. - SS Bag Tab Bracket, Single & Double Chute (4 required per meter). - SS Draw Latch, Single & Double Chute (2 required per meter). - Top Manifold Plate Seal, (2 required for single chute, 1 required for double chute). - Manifold Plate & Selector Seal, Double Chute (1 required for double chute). - Side Selector Seal, Double Chute (2 required per meter). - SS Lower Hardware Kit, Single Chute. - SS Lower Hardware Kit, Double Chute. - SS Manifold Bolt Kit, Double Chute, (1 kit required per run).

Single Chute Manifold Covers

- SS Manifold Cover, Single Chute, 4 run. - SS Manifold Cover, Single Chute, 6 run. - SS Manifold Cover, Single Chute, 8 run.

Double Chute Manifold Covers

- SS Manifold Cover, Double Chute, 4 run. - SS Manifold Cover, Double Chute, 6 run. - SS Manifold Cover, Double Chute, 8 run.

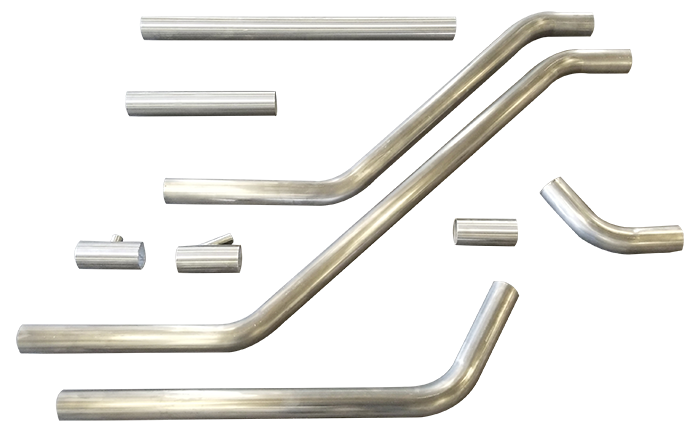

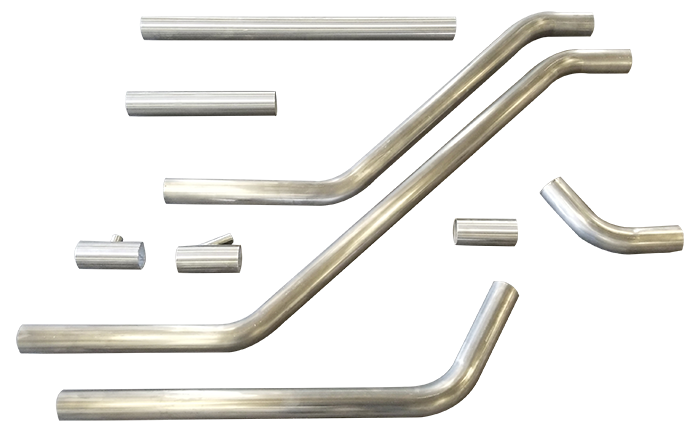

Features

- Top quality Mandrel bent piping in stock or made to order. - Straight piping cut to order.

Compatibility

- All John Deere pipes in stock. - Morris piping. COMING SOON!

Features

- 304 Stainless Steel system to replace the steel parts. - Precision built. - Parts sold individually or as a complete unit. - Plastic valve bodies. COMING SOON!

Compatibility

- For Case, Flexi Coil & New Holland.

Most durable & easy to use Quick Connector on the market

- Extra heavy-duty latch with tension adjustment. - Adjustable hex head set screws for added adjustment. - Heavy duty component compared to cast or steel products on market. - Complete set includes both halves, seals & latch. - Replacement seals available (QCseal).

Primary Heads

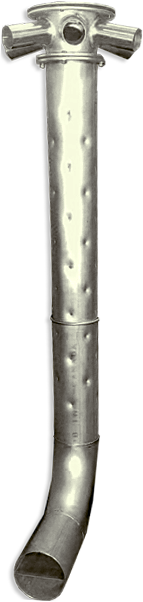

- Our primary heads are only compatible with our primary risers and vice versa. They do NOT fit OEM’s. - Our primary heads and risers can be ordered in 304 Stainless Steel. - Head has removable cap with ¼” rubber seal. - Available in 5" or 6" Inlet Size. - Available in 4 to 8 outlets. - Outlet Size is 2.5".

Primary Risers

- 90° bend. - 5” riser is 55” in height. - 6” riser is 60” in height. - Dimpled to assist even distribution. - Available Inlet Size 5" or 6".

Primary Mount

- Strong & Durable – mild steel only. - Includes U-bolts to suit Primary Riser & 4×4 frame.

Secondary Heads

- Designed to be the most durable, easiest to use, longest lasting head on the market. - Designed to prevent outlet hose blowout because the hoses are securely fastened to the outside of the outlets. - Easy access to entire head by removable rubber cap. - Gentle on seed design. - 1.25” OD and 1.5” outlet heads also available. - Morris flat fans. COMING SOON! - Includes exhaust clamp and a specially designed, soft on seed rubber cap (RC6) that seals securely to the head that will not blow off but can be easily removed to clear blockages. - All heads & risers are only available in 304 stainless steel. - Heads are electrostatically painted gloss black. - 2.5" Inlet, 1.00" Outlet, 4-15 Outlets. - 2.5" Inlet, 1.25" Outlet, 4-13 Outlets. - 2.5" Inlet, 1.50" Outlet, 4-8 Outlets.

Risers & Mounts

- Dimpling feature on secondary risers help to bring product to center of head to assist with even distribution. - 85° bend to limit seed damage in change of direction of product-flow. - RM2.5 – 2.5” powder coated stand-alone steel mount with hardware to give full flexibility for height and side to side adjustment. - All heads & risers are only available in 304 stainless steel.

Spreading Heads

- Allows spreading directly from a primary hose. - Spread high product rates & cover crops from primary hose in a cost-effective way. - Manufactured in 304 Stainless Steel.

Spreading Plates

- More even distribution from secondary hose for better ground cover. - Manufactured in 304 Stainless Steel.

AgCam

The AgCam Camera is the most durable agriculture backup camera; see what you’ve been missing The most rugged agricultural backup camera is built in the USA, the AgCam Camera. With a rating of IP69, the AgCam is 100% waterproof and dustproof. AgCam Cameras can withstand anything your sprayer, combine, cows, grain cart, or whatever your farm operation can throw at it. Need to see if your sprayer is clogged? AgCam can help. Need to see inside the hopper on your combine? AgCam has you covered. Watch your calves in the barn at any time. The AgCam Camera’s night vision distance of 75+ feet makes it easy to watch your herd. Looking for a grain cart camera that can help your business to be more profitable? These ideas are exactly what the AgCam Camera can do for you. The AgCam Camera can go anywhere you want with its triple hardened glass lens, anodized aluminum body, and triple o-ring seal. See how we put our camera to the test with our “Can We Break It?” video series. The versatility and durability of the AgCam Camera can’t be beat. These cameras take the worst conditions and keep performing.

Purchase Individually or as a Complete Kit

A variety of ordering options are available that range from complete systems for new customers or individual components to add to an existing system.

Wireless Capability

For tricky installations, AgCam can be installed with a wireless option. Wirelessly transmit video from a combines unloading auger to the cab of the combine and to the grain cart operator to assist with unloading on the go.

Bring Your Own Device

AgCam works with a variety of existing precision agriculture displays including the entire line of Trimble displays. When cab real estate is at a premium, integrating a camera system with an existing display can streamline the system and reduce the cost.

AgCam - Sunflower 9830 Air Drill

AgCam in use on a Sunflower 9830 Air Drill with tow behind cart. This video illustrates several great locations for a rear view camera.

OverView

The overview camera system delivers great images in an affordable package that is ideal for environments and usage that doesn’t require extreme ruggedness. Featuring a watertight camera body made from cast aluminum, it will provide years of dependable service. If you’re looking for a reliable, versatile, and cost-effective rearview camera system, then you won’t want to overlook the Dakota Micro Overview camera system.

Purchase Individually or as a Complete Kit

A variety of ordering options are available that range from complete systems for new customers or individual components to add to an existing system.

Wireless Capability

For tricky installations, OverView can be installed with a wireless option. Wirelessly transmit video from a combines unloading auger to the cab of the combine and to the grain cart operator to assist with unloading on the go.

Bring Your Own Device

OverView works with a variety of existing precision agriculture displays including the entire line of Trimble displays. When cab real estate is at a premium, integrating a camera system with an existing display can streamline the system and reduce the cost.

AgCam vs OverView

Explore the differences between the AgCam and OverView product lines to determine which solution is right for you.

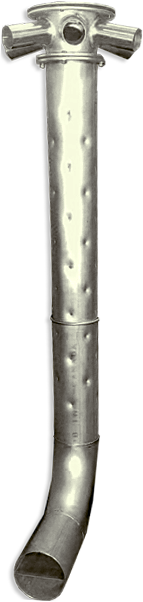

Sentinel™ Liquid Row Monitor

SureFire introduced the Sentinel™ Liquid Row Monitor in 2015 to bring liquid row monitoring into your existing in-cab display. In 2016, the Sentinel™ ISOBUS had a successful launch. Since that time, we have gained valuable information and feedback that will allow us to bring new and intuitive software enhancements this season with more coming in the near future. This large scale on-farm test confirms you will not find a more accurate system for your application needs!

Row-To-Row Accuracy that is Second-to-None

During Planting 2018, SureFire studied the row-to-row accuracy of LiquiShift combined with Metering Tube, planting 3000 acres of Irrigated and Dry Land corn with a 24 Row, 30″ planter. As our lab and engineering tests have shown previously, the accuracy is second-to-none. The farmer’s prescription applied from 10 to 40 GPA. SureFire analyzed over 50,000 data points logged from the Sentinel™ Liquid Row Monitor showing that the Row-to-Row CV (Coefficient of Variance) is less than 4.6% over 95% of the time. The average CV is just 3.9%.

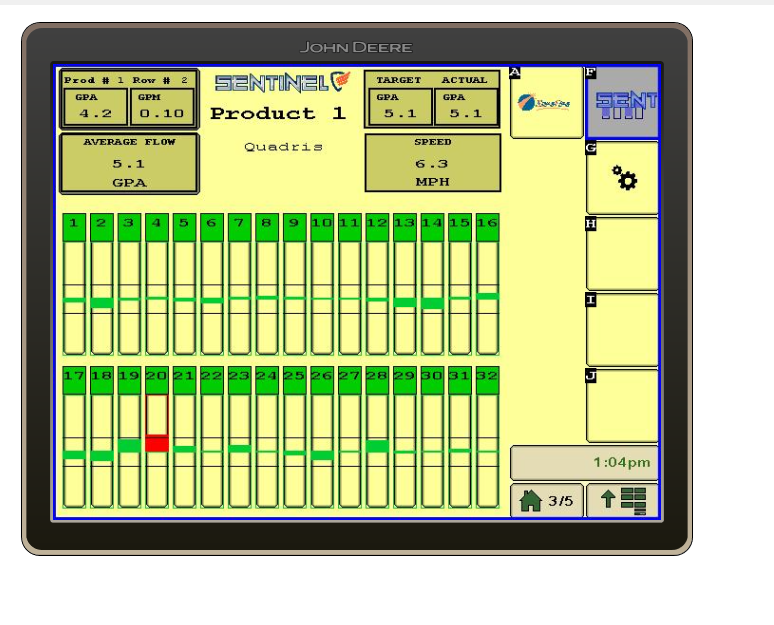

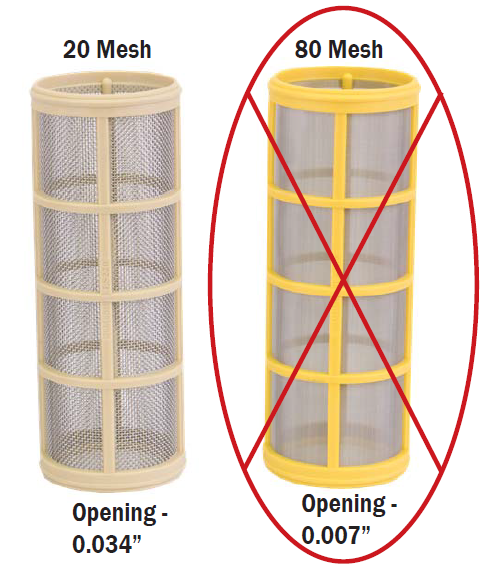

20 Mesh – That’s all you need!

20 Mesh – That’s all you need! Nearly all SureFire systems, including Sentinel™, only require a 20 Mesh Strainer. A 20 mesh screen has 385% larger passageway size and 48% more open area than an 80 mesh screen. If you are tired of cleaning filters and unplugging orifices, SureFire has a system for you. The Sentinel™ system allows in cab monitoring of the fertilizer flow to every row of a planter or applicator. This replaces the floating ball flow monitor with an in cab display and alarm to immediately alert the operator when the flow for any row is above or below the intended rate. Whether it is a plugged row or a leak, the operator will know immediately. This will nearly eliminate a crop planted without the proper fertilizer or pesticide. -Much more than a blockage monitor, Sentinel™ also lets you know when flow is slightly reduced, not just completely blocked. -Sentinel™ works great for prescription application. Sentinel’s auto-rate feature measures and calculates the average rate of all rows and identifies rows under or over this variable prescription rate. -Flows are displayed in both gallons per minute and gallons per acre to easily understand system performance. -Audio alarm alerts the operator within seconds when a row is under or over applying. -Independent set points for % over or % under rate.

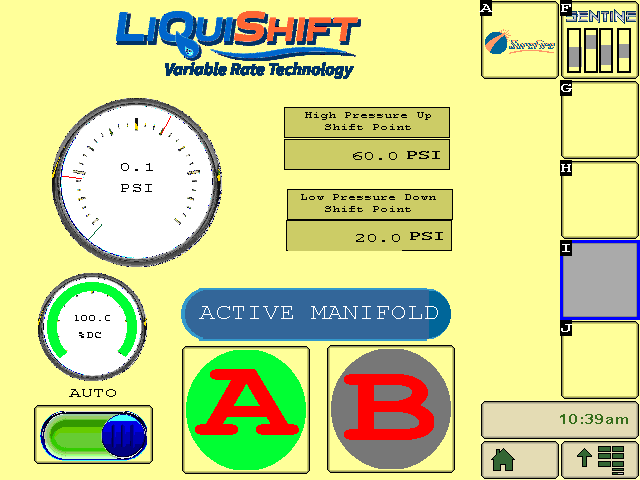

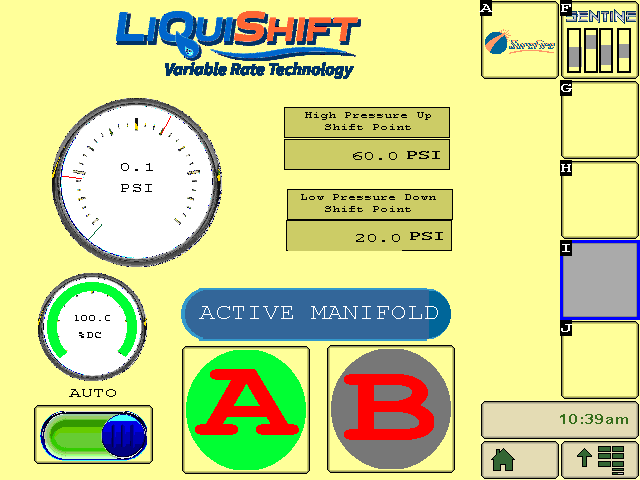

LiquiShift® integration with Sentinel™ ISO

The SureFire LiquiShift® is fully integrated with the Sentinel™ ISO controller. This feature allows you to monitor the system pressure and adjust the pressure shift points for more customization options. This combination also allows you to manually switch between the two metering tubes from the cab. On screen information allows you to monitor the pump duty cycle and visually see which metering tube is currently being used.

LiquiShift® takes Metering Tube to the NEXT Level!

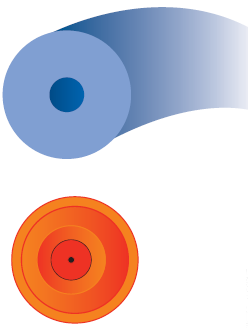

LiquiShift® allows the installation of two metering tubes on each row. Special software developed by SureFire monitors the system pressure and automatically shifts between the two metering tubes on each row, keeping the LiquiShift® plumbing package in a pressure sweet spot.

Why Metering Tube?

SureFire loves to use Metering Tube in place of a traditional disc orifice to provide even distribution to each row. In a typical in-furrow application scenario, a 0.030″ orifice is replaced with an 8′ length of metering tube having a passageway of 0.096″. The combination of length and diameter equalizes flow to each row. Metering tube eliminates the problem of plugged orifices and the need to run small strainers to keep small mechanical components and orifices from plugging. Metering tube size varies from 0.080″ to 0.187.” With Metering Tube, just a 20 Mesh Strainer is needed to “get out the big chunks!”

20 Mesh – That’s all you need!

The liquid systems are working well with no issues. Accuracy seems to be very good both in total gallons applied per acre and row to row consistency. We have planted a little over 4000 acres without plugging a single row which far exceeds my expectations.” ~Kriss S.

LiquiShift® takes Metering Tube to the NEXT Level!

LiquiShift® allows the installation of two metering tubes on each row. Special software developed by SureFire monitors the system pressure and automatically shifts between the two metering tubes on each row, keeping the LiquiShift® plumbing package in a pressure sweet spot.

Why LiquiShift®?

LiquiShift® Variable Rate Technology provides the ability to achieve the widest range of on-the-go rate changes of any application system available. SureFire’s LiquiShift® will allow for a flow increase of 6-8 times the minimum flow rate the system is configured for. In a scenario with a minimum rate of 10 GPA at 4 MPH, the maximum rate at 6 MPH would be 40-50 GPA (6-8 times the minimum rate).

Prescription Applications

Achieve your agronomic objectives without limitations. You will no longer narrow the range of your liquid prescriptions to get within the achievable range of a single orifice size. With 6-8 times flow capacity your agronomist is in the driver’s seat. When the analysis calls for 8 GPA in low-productive or areas with high residual nutrients, you will apply 8 GPA. When the analysis calls for 45 GPA in the high productive “black-soil” region of the field, you will apply 45 GPA. No longer will you be forced to over-apply in the poor performing areas.

AG 24 Months at 0% Interest!

Applies to Trimble Agricultural Equipment. ● Minimum transaction size is $5,000. ● Applies to new equipment only. ●Trimble Extended Warranty can be included. ●Available only through Trimble Financial Service Providers. ●All applications are subject to credit approval and the customer is responsible for all applicable taxes. Rates + participation fees are subject to change. ● Tax laws vary. Trimble Financial Services’ funding partner will add, and the customer shall be responsible to pay, all applicable taxes. ● Use the standard Trimble Financial Services lease application form. Enter the equipment description and cost in the proper space on the form. Under Lease Term enter “Trimble 24.” ● Lease Payment Calculation Information: ○ Simply divide the new equipment cost by .04186 for the monthly payment. Only one payment in advance, a $100 document fee and $1/EFA at the end of lease to take ownership.

AG 36 Months at 2.99% Interest!

0% for 36 months with cash down equal to one annual payment First payment: Due up front Schedule: 3 annuals Minimum Transactrion Size $20,000

AG 60 Months at 4.99% Interest!

4.99% for 60 months with cash down equal one annual payment First payment: Due up front Schedule: 5 annuals starting in 12 months Minimum transaction Size $20,000 Program Eligibility All PTx Trimble products, installation, and standard freight are eligible and may be used in conjunction with other PTx Trimble discount programs.

Trade-up Program: AG-372 Receiver to an AG-392 Receiver

Description: For a limited time, you can trade in an AG-372 262 and 252 GNSS receiver for the latest AG-392 GNSS receiver. Contact your GPS Ontario Sales Representative for more information or to Request a Quote. Program Start: 15 July 2024 Program End: 31 December 2024 Save Upto 6000.00 off a new Receiver with your Trade.